4 Facts About Pipe Coiling

1. What is Pipe Coiling?

The pipe coiling process requires specialized machinery to take the straight pipe and coil it, either ending up with one coil or multiple coils. Pipes of all kinds of lengths and diameters can be used for pipe coiling. Coiling pipes allows for some customization, from the bend diameter to the helix pitch.

2. Pipe Bending – How It’s Done

Pipe coiling can be done by a few different machines, some of which require constant manual operation, while others are controlled by a computer for consistency. Either way, all of these machines are complex, but they are necessary for creating coiled pipes.

The Spinning Drum

With the spinning drum, the pipe is placed on the drum and guided to a separate roller which bends the pipe into a spiral.

Three-Roll Bender

As the name implies, there are three rollers used in this machine. Two of them guide the pipe under a third roller, which bends the pipe while operators apply lateral force to form the spiral.

Pitch Rolling Bender

This machine works much like the three-roll bender. One of the main differences is that, unlike the three-roll bender requires manual operation, this machine does not. Instead, more rollers are used for shaping the spiral, and different versions might use more rollers for variations of the spiral’s shape.

Two-Disc Coil Bender

The two-disc coil bender is somewhat like the spinning drum, but accommodates longer pipes and tubes. This machine uses a spindle (which the pipe is wrapped around) and rollers to form a spiral. Notably, all of these machines are expensive, and require trained professionals to operate them safely. This is a job where it’s best to hire a Tulsa metal fabricator to handle it.

3. Coiled Pipe Uses

Many industries need coiled piping, from distillation to refrigeration.In the refrigeration industry, coiled pipes are necessary for heat exchange, due to their larger surface area compared to straight pipes. With the coiled pipes, the refrigerant can heat up and cool down faster than it could with a straight pipe. For the air conditioning industry, the evaporator system inside the air conditioning system requires coiled pipe. If you use a geothermal system, the ground loop is often made using coiled piping, since it doesn’t take up as much space as other pipes. Distilleries needs coiled pipe, too, whenever they distill liquor like vodka or whiskey. Alcohol vapor from impure fermented liquid travels through the coiled copper pipe (placed in a cold water container), and the alcohol vapors cool down. When they do, they condense and the result is distilled alcohol. For the oil industry, coiled piping is unwound and injected into oil wells using specialized machinery. Coiled pipe presents less problems than traditional piping, and has a few uses. Usually, it’s used for bringing oil out of the well or for chemical injection into oil wells. Find: Local Dentist>> Many more industries use it, and if you belong to an industry in need of coiled pipes, contact a local custom pipe bending company.

4. Types of Pipes Good for Coiling

If the pipe is made of a malleable metal, then it can be coiled. Kinds of bendable pipes include:

- Copper pipes

- Stainless steel pipes

- Aluminum pipes

- Galvanized steel pipes

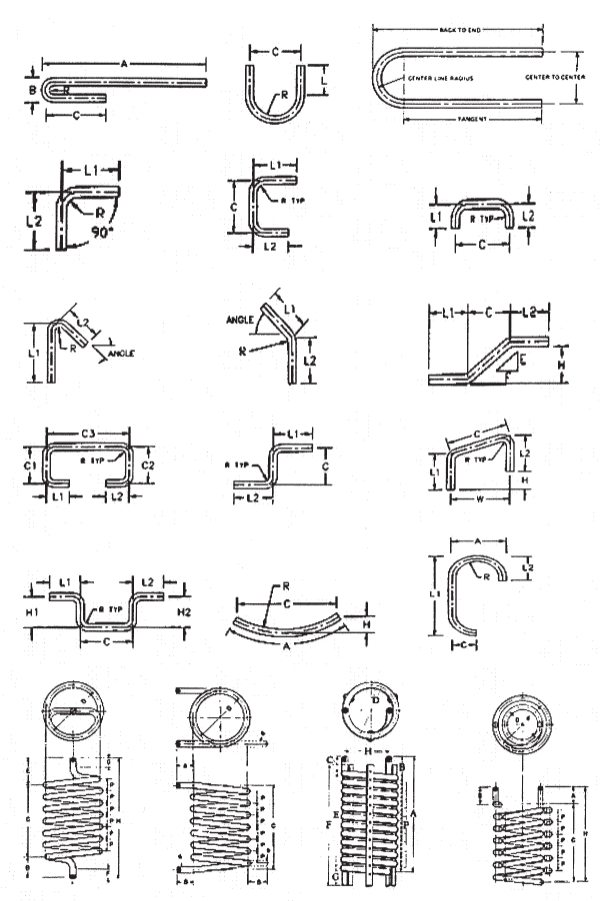

It doesn’t matter the pipe’s wall thickness or diameter, with the right equipment and training it can be coiled. There are even several different styles of coils for the pipes, including flat, nested coils, and single helices. If you or your company are in need of coiled piping or tubing, contact a Tulsa pipe bending service near you.